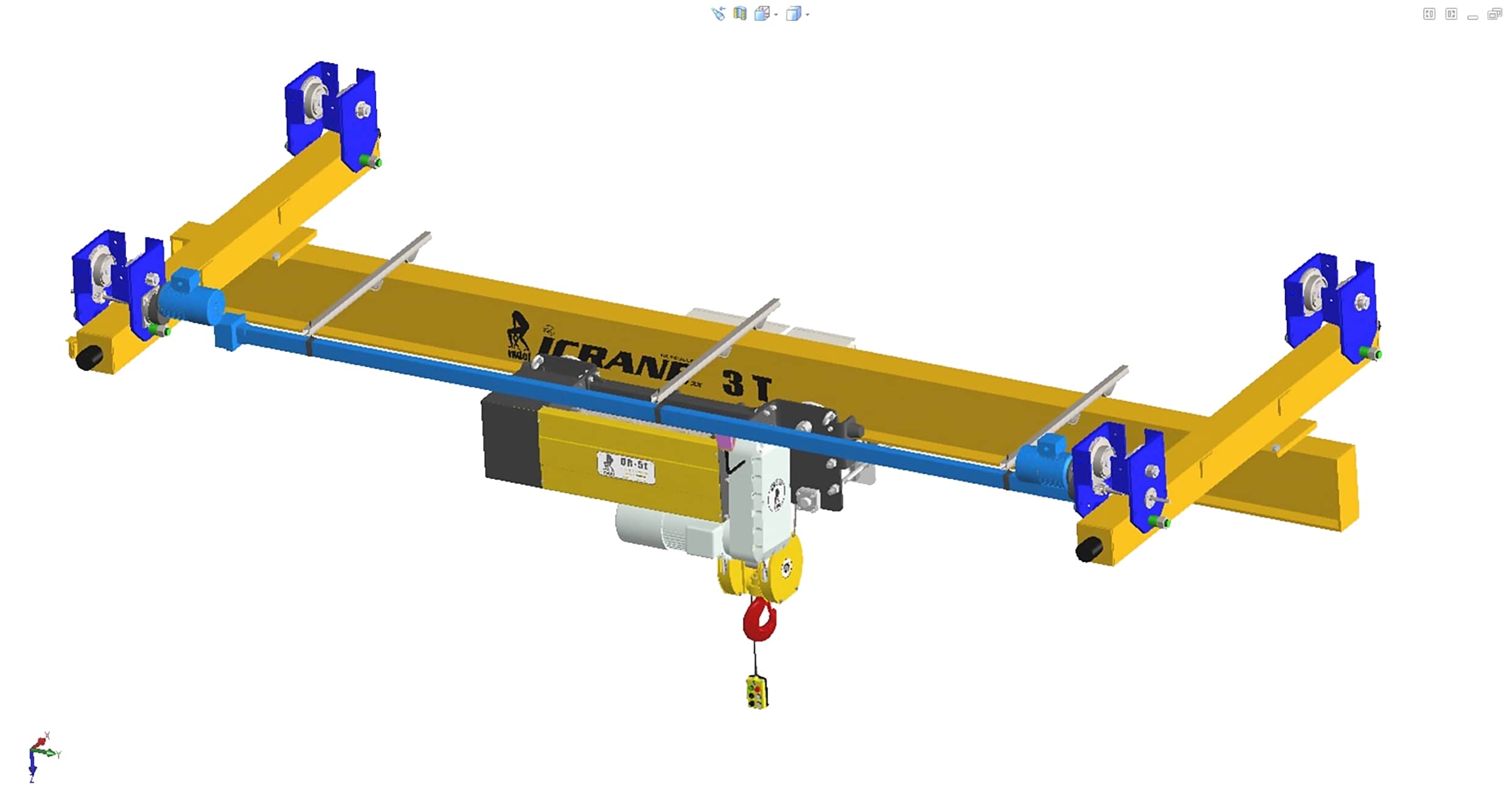

Single Girder – Underslung Crane

| FEATURES |

| Underslung cranes are proven to maximize customer floor space and mobility |

| The cranes are typically attached to the existing roof structure—columns to support the crane runway are not needed |

| The installation of stand-alone steel superstructures also enables the solution to be flexible to production requirements |

| BENEFITS |

| ENGINEERED FOR APPLICATION |

| Optimum utilization of height and space through specialized crane and girder design software, making it flexible for new or existing structures without extensive change to structures |

| UR series hoist offered as standard features low head room design and favorable hook path |

| Lateral overhangs to extend the cross-travel path beyond the runway |

| End carriage designed for suitability with runway beams |

| HIGH EFFICIENCY |

| Offered with proven components selected for a long service life and high degree of reliability |

| German designed and built gear box and motor for hoisting and travel applications offered as standard |

| Low operation and maintenance costs, high uptime arising from optimized design |

| High range of options to meet customer requirements |

| CONSISTENT PERFORMANCE |

| Smooth handling and exact positioning of loads when supplied with VFD |

| Torsional rigidity of girder and end carriages and favorable utilization of available height and space with state-of-the-art design technology |

| Component selection and technology devised to be user friendly and for efficient load handling and reduced maintenance |

SWL UP TO: 12.5 T

SPAN UP TO: 18 Meters

LONG TRAVEL (LT) SPEED UP TO: 40 M/MIN

CROSS TRAVEL (CT) SPEED UP TO: 20 M/MIN

HOISTING SPEED UP TO: 8 M/MIN

HOISTING/ TRAVEL SPEED: DUAL SPEED OFFERED AS STANDARD VFD (Optional)